Closed Wedge Socket|Wire Rope Wedge Sockets

Closed Wedge Socket is used as the wire rope end terminations to attach the wire to a fixed point. Compared with mooring spelter poured socket, the installation of wedge sockets will be easier by pushing back the wedge, and then the rope will be reeved. The closed wedge & basket will be quenched & tempered for maximum high tensile strength of the cast steel.

- Material: Cast alloy steel with high mechanical properties.

- Finish: hot dipped galvanized, Painting or upon request.

- Temperature Range: -20°C up to +200°C. Use at higher temperatures possible with reduction of WLL.

- Standard: Federal RR-S-550/EN 13411-6.

- The efficiency of a 6 and 8 strand wire rope/wedge socket connection is 80% of the minimum breaking load of the wire but limited to the minimum breaking load of the socket (MBL)

- Packing: Carton with pallet.

- Rope Sizes: From 18mm to 86mm.

- Bespoke sizes are available.

- Applications: lifting, rigging, towing and constructions..

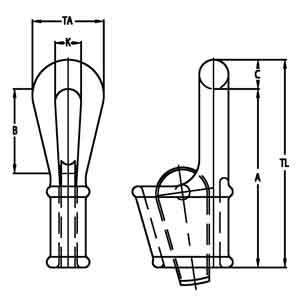

Specifications:

| For wire Ø | A mm | B mm | C mm | K mm | TA mm | TL mm | WT kg/ea | MBL Ton |

|---|---|---|---|---|---|---|---|---|

| 18-19 | 220 | 100 | 34 | 40 | 90 | 254 | 7 | 40 |

| 20-22 | 225 | 225 | 42 | 47 | 110 | 267 | 9 | 55 |

| 24-26 | 290 | 130 | 50 | 55 | 125 | 340 | 14 | 75 |

| 27-29 | 325 | 145 | 60 | 70 | 152 | 385 | 22 | 90 |

| 30-32 | 360 | 160 | 68 | 75 | 165 | 428 | 30 | 110 |

| 34-36 | 400 | 180 | 68 | 75 | 165 | 468 | 38 | 125 |

| 37-39 | 500 | 240 | 72 | 80 | 185 | 572 | 49 | 150 |

| 40-42 | 600 | 310 | 80 | 90 | 210 | 680 | 65 | 170 |

| 43-48 | 640 | 325 | 90 | 100 | 225 | 730 | 100 | 225 |

| 49-52 | 720 | 375 | 100 | 110 | 245 | 820 | 150 | 280 |

| 54-58 | 775 | 400 | 110 | 120 | 265 | 885 | 175 | 360 |

| 61-64 | 900 | 470 | 120 | 130 | 290 | 1020 | 230 | 425 |

| 72-76 | 1000 | 500 | 130 | 150 | 330 | 1130 | 300 | 460 |

| 81-86 | 1125 | 550 | 135 | 165 | 360 | 1260 | 425 | 625 |

Instructions:

- before use always inspect the socket, the wedge, and the pin

- always be sure that socket and wedge have the correct size for the wire rope diameter

- when installing the wire rope, always pre-load the wedge with the wire rope in place.

- never weld the tail on standard wire rope; the tail should have a length of at least 6 times the wire rope diameter with a minimum of 150 mm, secure the dead end of the rope with a wire rope clip.

- before applying the first load always use a hammer to seat the wedge and rope as deep as possible into the socket

- check the assembly regularly to re-tighten or re-position if necessary

- never side-load the wedge socket as it has not been designed for that purpose

- the load may slip if the connection is not properly installed

- the efficiency of a wire rope – wedge socket connection is 80% of the minimum breaking load of the wire but limited to the minimum breaking load of the socket.

Views: 121